Focus on DTF & UV DTF inkjet printing solution

The Ultimate Guide To DTG Transfer Film: How To Create Professional-Quality Prints

Are you looking to take your printing game to the next level? Look no further than our comprehensive guide to DTG transfer film. In this article, we will show you step-by-step how to create professional-quality prints that will wow your customers and elevate your brand. Whether you are a beginner or a seasoned pro, this ultimate guide has everything you need to know to master the art of DTG transfer film. So, what are you waiting for? Let's get started!

- Understanding DTG Transfer Film and Its Benefits

DTG transfer film, also known as direct-to-garment transfer film, is a revolutionary product that has transformed the way professional-quality prints are created. In this ultimate guide, we will delve into the intricacies of DTG transfer film, its benefits, and how you can use it to create stunning prints.

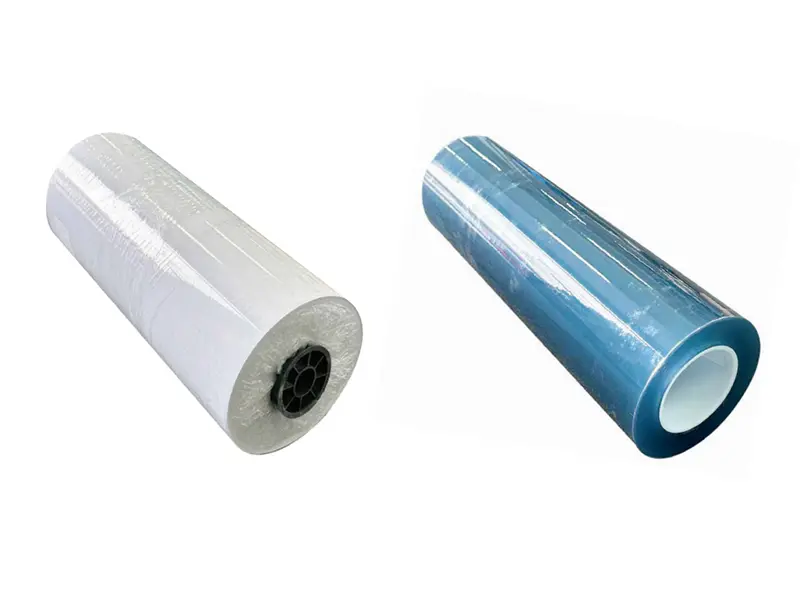

DTG transfer film is a thin, flexible material that is used in the direct-to-garment printing process to transfer designs onto fabrics. Unlike traditional screen printing, DTG transfer film allows for intricate designs and vibrant colors to be transferred with ease and precision. This results in a high-quality, professional-looking print that is sure to impress.

One of the biggest benefits of DTG transfer film is its versatility. It can be used on a wide range of fabrics, including cotton, polyester, and blends. This means that you can create prints on a variety of garments, from t-shirts and hoodies to hats and bags. Whether you are a small business looking to create custom merchandise or a clothing brand looking to produce unique designs, DTG transfer film is the perfect solution.

Another advantage of DTG transfer film is its durability. The film is designed to withstand multiple washes and wear, ensuring that your prints will last for years to come. This durability is especially important for clothing brands and businesses looking to create long-lasting products that customers will love.

In addition to its versatility and durability, DTG transfer film is also easy to use. With a heat press and a few simple steps, you can transfer your designs onto fabrics in a matter of minutes. This makes DTG transfer film a cost-effective and time-saving option for businesses and individuals looking to create professional-quality prints.

When using DTG transfer film, it is important to keep a few key tips in mind. First, make sure to choose the right type of film for your fabric. Different films are designed for different fabrics, so be sure to read the product specifications before making a purchase. Additionally, be sure to follow the instructions carefully when using the film with a heat press to ensure proper adhesion and longevity of the print.

In conclusion, DTG transfer film is a game-changer in the world of professional printing. Its versatility, durability, and ease of use make it an ideal choice for businesses and individuals looking to create high-quality prints on a variety of fabrics. Whether you are a small business owner or a clothing designer, DTG transfer film is a must-have tool for creating stunning prints that will impress your customers.

- Selecting the Right Materials for Professional-Quality Prints

In the world of garment printing, achieving professional-quality prints is essential for success. One crucial factor in creating top-notch prints is selecting the right materials, particularly DTG transfer film. This article serves as the ultimate guide to understanding and utilizing DTG transfer film to create professional-quality prints.

DTG transfer film, also known as direct-to-garment transfer film, is a special type of film used in the process of transferring designs onto garments using a direct-to-garment printer. This film acts as a temporary carrier for the ink, allowing for precise placement of the design onto the garment. When choosing DTG transfer film, it is important to consider factors such as thickness, adhesion, and compatibility with different types of ink and garment materials.

Thickness is a critical factor to consider when selecting DTG transfer film. Thicker films tend to be more durable and provide better adhesion to the garment, resulting in a long-lasting print. However, thinner films are often preferred for delicate materials or designs with fine details. It is essential to choose a film that is the right thickness for the specific requirements of your print job.

Adhesion is another crucial consideration when selecting DTG transfer film. The film must adhere securely to the garment to prevent any shifting or wrinkling during the printing process. A good quality film will have strong adhesion properties, ensuring that the design stays in place throughout the printing and transfer process. Additionally, the adhesion properties of the film will impact the durability and washability of the final print.

Compatibility with different types of ink and garment materials is also important when choosing DTG transfer film. Some films are specifically designed to work with certain types of ink, such as water-based or eco-solvent inks. It is crucial to select a film that is compatible with the ink you are using to ensure optimal print quality. Additionally, the film should be suitable for use with a variety of garment materials, including cotton, polyester, and blends.

In conclusion, selecting the right DTG transfer film is essential for creating professional-quality prints. By considering factors such as thickness, adhesion, and compatibility with ink and garment materials, you can ensure that your prints are of the highest quality. Remember to choose a film that meets the specific requirements of your print job to achieve the best results. With the right DTG transfer film, you can create stunning prints that are sure to impress.

- Step-by-Step Guide to Creating DTG Transfer Film Prints

DTG (Direct-to-Garment) printing has revolutionized the world of custom apparel, allowing for high-quality prints with a wide range of colors and intricate details. With the advancements in technology, DTG transfer film has become an essential tool for creating professional-quality prints. In this comprehensive guide, we will take you through a step-by-step process on how to create DTG transfer film prints that will elevate your designs to the next level.

Step 1: Choosing the Right Transfer Film

The first step in creating DTG transfer film prints is selecting the right transfer film for your project. There are various types of transfer films available, each with its own unique properties and capabilities. When choosing a transfer film, consider factors such as the type of fabric you will be printing on, the complexity of your design, and the desired finish of the print.

Step 2: Preparing your Design

Once you have chosen the right transfer film, it's time to prepare your design. Use a graphic design software to create or upload your design, making sure to adjust the size and colors as needed. Keep in mind that DTG transfer film prints can capture even the smallest details, so make sure your design is crisp and clear.

Step 3: Printing the Film

After finalizing your design, it's time to print the transfer film. Load the transfer film into your printer and adjust the settings for optimal print quality. Make sure to print the design in mirror image, as this will ensure that the final print appears correctly on the garment. Once the film is printed, carefully cut around the design to remove any excess film.

Step 4: Preparing the Garment

Before applying the transfer film to the garment, make sure the fabric is clean and free of any dust or debris. Use a heat press to pre-heat the garment, which will help the transfer film adhere to the fabric more effectively. Place the garment on the heat press and adjust the temperature and pressure settings according to the transfer film manufacturer's instructions.

Step 5: Applying the Transfer Film

Carefully place the transfer film on the pre-heated garment, making sure it is positioned correctly and securely. Use a heat press to apply pressure and heat to the transfer film, activating the adhesive and bonding it to the fabric. Be sure to follow the recommended time and temperature settings to ensure a durable and vibrant print.

Step 6: Removing the Film

After applying heat and pressure, carefully peel off the transfer film from the garment to reveal your professionally-printed design. The transfer film should come off easily, leaving behind a smooth and vibrant print on the fabric. Allow the garment to cool before handling or wearing it.

In conclusion, DTG transfer film is a versatile and powerful tool for creating professional-quality prints on a wide range of fabrics. By following this step-by-step guide, you can create stunning designs that will impress even the most discerning customers. Experiment with different transfer films and design techniques to unleash your creativity and take your custom apparel business to new heights.

- Tips and Tricks for Enhancing Your DTG Transfer Film Prints

DTG transfer film printing has revolutionized the way we create professional-quality prints. This article will provide you with essential tips and tricks to enhance your DTG transfer film prints.

One of the key factors in creating high-quality DTG transfer film prints is the type of transfer film you use. Opt for a high-quality transfer film that is specifically designed for DTG printing to ensure vibrant colors and sharp details in your prints. Choose a transfer film that has a smooth surface and is compatible with your DTG printer for optimum results.

Another important aspect to consider when creating DTG transfer film prints is the preparation of your artwork. Make sure your design is properly sized and positioned on the transfer film to ensure accurate placement on your garment. Pay attention to details such as text alignment and image resolution to avoid any printing errors.

When printing with DTG transfer film, it is crucial to adjust the printer settings to achieve the desired result. Experiment with different settings such as resolution, ink density, and color profiles to find the optimal combination for your prints. Test a small sample print before committing to a large batch to ensure the final result meets your expectations.

To enhance the durability of your DTG transfer film prints, consider using a heat press machine to properly adhere the transfer film to the garment. Apply even pressure and heat to ensure a secure bond between the film and the fabric. Follow the manufacturer's instructions for the correct time and temperature settings to prevent any damage to the print.

After transferring the film to the garment, allow it to cool completely before peeling off the backing. This will ensure that the print sets properly and lasts longer. Avoid stretching or pulling the garment during this process to prevent any distortion of the print.

In conclusion, creating professional-quality DTG transfer film prints requires attention to detail and experimentation with different techniques. By following the tips and tricks outlined in this article, you can enhance the quality and durability of your prints. Remember to invest in high-quality transfer film, prepare your artwork properly, adjust printer settings accordingly, and use a heat press machine for secure adhesion. With practice and patience, you can achieve stunning results with DTG transfer film printing.

- Troubleshooting Common Issues with DTG Transfer Film Prints

Dye-sublimation printing is a popular method for creating high-quality, vibrant prints on a variety of surfaces. DTG transfer film is an essential tool in this process, allowing for crisp, detailed images to be transferred onto garments and other materials. However, like any printing method, there can be common issues that arise during the printing process that may affect the final result. In this article, we will explore some of the most common issues that can occur with DTG transfer film prints and how to troubleshoot them effectively.

One common issue that may arise when using DTG transfer film is poor image quality. This can be caused by a variety of factors, including incorrect settings on the printer, low-quality transfer film, or an outdated design file. To troubleshoot this issue, first, check the print settings on your printer to ensure they are optimized for the type of transfer film you are using. Additionally, make sure you are using high-quality transfer film that is compatible with your printer and has not expired. Finally, double-check your design file to ensure it is properly formatted and high-resolution.

Another common issue with DTG transfer film prints is ghosting or blurring of the image. This can occur when the transfer film does not adhere properly to the substrate, resulting in a blurry or distorted image. To troubleshoot this issue, make sure you are applying the transfer film correctly and using enough pressure during the transfer process. Additionally, check the temperature and pressure settings on your heat press to ensure they are properly calibrated for the type of transfer film you are using.

One of the most frustrating issues that can occur with DTG transfer film prints is color bleeding or fading. This can happen when the ink used in the printing process is not properly set or when the transfer film is not heat pressed for a sufficient amount of time. To troubleshoot this issue, double-check the settings on your heat press to ensure the transfer film is being pressed at the correct temperature and pressure for the recommended amount of time. Additionally, consider using a heat-resistant cover sheet to protect the transfer film and prevent color bleeding.

In conclusion, DTG transfer film is a valuable tool for creating professional-quality prints, but it is essential to troubleshoot common issues that may arise during the printing process. By following the tips outlined in this article, you can ensure that your DTG transfer film prints turn out crisp, vibrant, and free of any imperfections. Remember to always double-check your settings, use high-quality materials, and pay close attention to the transfer process to achieve the best results possible.

Conclusion

In conclusion, mastering the art of DTG transfer film is crucial for achieving professional-quality prints. By following the steps outlined in this ultimate guide, you can enhance the quality and durability of your prints, ensuring your designs stand out and make a lasting impression. Whether you are a seasoned printer or just starting out, investing time in learning and perfecting the process of DTG transfer film will undoubtedly elevate your printing game. So, don't hesitate to experiment, practice, and refine your techniques to create stunning and long-lasting prints that will wow your customers and leave a lasting impact in the industry.

Email: sales@bigfootdg.com

Add: 4th Floor, Unit 6, Building 11, West Area, Qingyang Street Electronics & Electrical Industrial Park, Zhongyuan District, Zhengzhou City, Henan Province, China