Focus on DTF & UV DTF inkjet printing solution

Dive Into DTF Printing With UV-Curable PET Film

Welcome to the exciting world of DTF printing with UV-Curable PET Film! In this article, we will delve into the innovative technique of Direct-to-Film printing and explore the endless possibilities it offers for creating vibrant and durable designs. Whether you are a seasoned printing professional or a novice looking to expand your skills, this article will provide valuable insights into how this cutting-edge technology can revolutionize your printing projects. Join us as we take a deep dive into the world of DTF printing and discover the power of UV-Curable PET Film.

Understanding DTF Printing Technology

Dive into DTF Printing with UV-Curable PET Film: Understanding DTF Printing Technology

DTF printing, also known as direct-to-film printing, is a modern printing technique that allows for high-quality, full-color designs to be transferred onto a variety of surfaces, including fabrics, ceramics, and more. One of the key components of DTF printing is the use of UV-curable PET film, which plays a crucial role in the transfer process.

UV-curable PET film is a type of printable film that is coated with a special UV-curable ink that hardens when exposed to ultraviolet light. This allows for vibrant and durable prints that are resistant to fading, scratching, and other forms of damage. In DTF printing, the PET film is used as a carrier for the design, which is then transferred onto the final surface using heat and pressure.

One of the main advantages of using UV-curable PET film in DTF printing is its ability to produce prints with incredibly sharp detail and vibrant colors. The UV-curable ink used in this process allows for precise and accurate color reproduction, making it ideal for printing high-resolution images and intricate designs. Additionally, the UV-curable ink is more environmentally friendly than traditional solvent-based inks, as it does not release harmful VOCs into the air.

Another benefit of UV-curable PET film is its versatility. It can be used to print on a wide range of surfaces, including fabrics, plastics, glass, and metal. This makes DTF printing with UV-curable PET film ideal for a variety of applications, from custom clothing and accessories to signage and promotional materials.

In addition to its quality and versatility, UV-curable PET film is also known for its durability. The UV-curable ink creates a strong bond with the final surface, ensuring that the design will not peel, crack, or fade over time. This makes UV-curable PET film a popular choice for applications that require long-lasting and high-quality prints.

Overall, DTF printing with UV-curable PET film offers a range of benefits for businesses and individuals looking to create high-quality, vibrant prints. Its ability to produce sharp detail and accurate colors, along with its versatility and durability, make it an excellent choice for a wide range of applications. Whether you're looking to create custom clothing, promotional materials, or signage, DTF printing with UV-curable PET film is a versatile and reliable option to consider.

Exploring the Benefits of UV-Curable PET Film

UV-Curable PET film is a revolutionary technology that is transforming the world of direct-to-film (DTF) printing. This innovative material offers a wide range of benefits for businesses looking to enhance their printing capabilities and create high-quality products. In this article, we will explore the many advantages of UV-Curable PET film and how it can help take your printing projects to the next level.

One of the key benefits of UV-Curable PET film is its ability to provide superior image quality. This material is specially designed to enhance the color vibrancy and sharpness of printed images, resulting in crisp and clear graphics that are sure to impress. Whether you are printing logos, graphics, or photos, UV-Curable PET film can help bring your designs to life with stunning clarity and detail.

In addition to its exceptional image quality, UV-Curable PET film is also incredibly durable and long-lasting. This material is resistant to scratches, fading, and water damage, ensuring that your printed products will maintain their beauty and integrity for years to come. Whether you are creating outdoor signage, window displays, or promotional materials, UV-Curable PET film is a reliable choice that will stand the test of time.

Another advantage of UV-Curable PET film is its versatility and ease of use. This material can be easily applied to a wide range of surfaces, including plastics, glass, metal, and more, making it ideal for a variety of printing projects. Whether you are printing on flat or curved surfaces, UV-Curable PET film can conform to the shape of the object with ease, ensuring a seamless and professional finish every time.

Furthermore, UV-Curable PET film is environmentally friendly and sustainable. This material is free of harmful chemicals and toxins, making it safe for both the environment and the people who come into contact with it. By choosing UV-Curable PET film for your printing projects, you can reduce your carbon footprint and make a positive impact on the planet.

In conclusion, UV-Curable PET film is a game-changer for businesses looking to elevate their printing capabilities and create stunning products. With its superior image quality, durability, versatility, and eco-friendly properties, this innovative material is a must-have for any printing project. Whether you are a small business owner, a graphic designer, or a printing professional, UV-Curable PET film can help take your creations to the next level. Start exploring the benefits of UV-Curable PET film today and see the difference it can make in your printing projects.

Choosing the Right Materials for DTF Printing

When it comes to choosing the right materials for Direct to Film (DTF) printing, one of the most popular options in the market is UV-curable PET film. This versatile and durable material is ideal for creating high-quality prints with vibrant colors and sharp details. In this article, we will discuss the benefits of using UV-curable PET film for DTF printing and provide tips on how to choose the right materials for your specific printing needs.

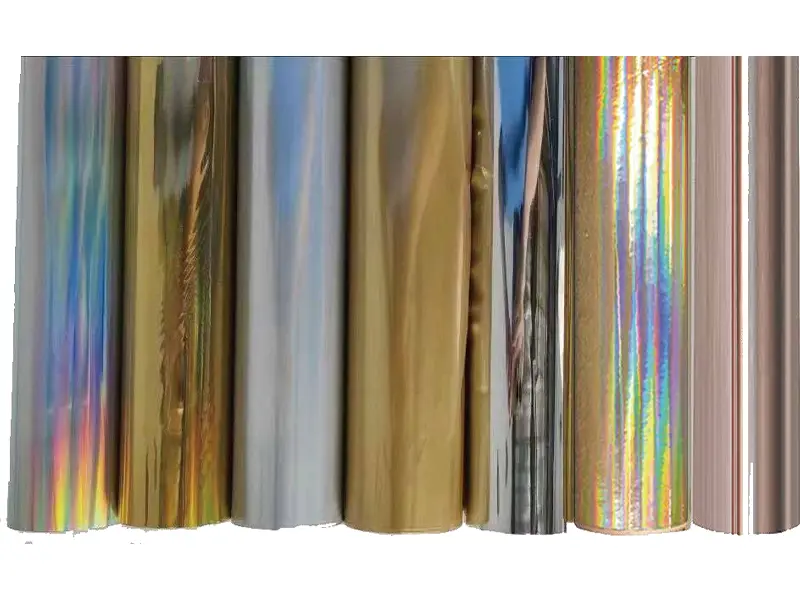

UV-curable PET film is a type of polyester film that is coated with a UV-curable ink. This ink is cured using ultraviolet light, which creates a durable and long-lasting print. The PET film itself is also highly resistant to moisture, heat, and chemicals, making it ideal for a wide range of applications. Additionally, UV-curable PET film is available in a variety of thicknesses and finishes, allowing you to choose the right material for your specific printing needs.

One of the main benefits of using UV-curable PET film for DTF printing is its excellent print quality. The UV-curable ink adheres well to the PET film, resulting in prints that are vibrant, sharp, and resistant to fading. This makes UV-curable PET film ideal for printing high-resolution images, logos, and text. Additionally, the UV-curable ink dries quickly and does not require any additional curing time, making the printing process fast and efficient.

In addition to its excellent print quality, UV-curable PET film is also highly durable. The PET film is resistant to tears, wrinkles, and abrasions, making it ideal for printing applications that require a lot of handling. Additionally, the UV-curable ink is scratch-resistant and UV-resistant, ensuring that your prints will remain vibrant and sharp even in harsh environmental conditions. This durability makes UV-curable PET film perfect for outdoor signage, banners, decals, and other applications that require long-lasting prints.

When choosing the right materials for DTF printing with UV-curable PET film, there are a few factors to consider. First, consider the thickness of the PET film. Thicker films are more durable and tear-resistant, making them ideal for applications that require frequent handling. However, thinner films may be more flexible and easier to work with. Additionally, consider the finish of the PET film. Glossy finishes are ideal for applications that require vibrant colors and high gloss, while matte finishes are ideal for applications that require a more subtle and professional look.

In conclusion, UV-curable PET film is a versatile and durable material that is ideal for DTF printing. Its excellent print quality, durability, and resistance to fading make it perfect for a wide range of applications. When choosing the right materials for DTF printing with UV-curable PET film, consider the thickness and finish of the film to ensure that you achieve the best results for your specific printing needs.

Step-by-Step Guide to DTF Printing with UV-Curable PET Film

Dive into DTF Printing with UV-Curable PET Film: Step-by-Step Guide

DTF printing, also known as direct-to-film printing, is a popular method used in the textile industry to transfer designs onto various fabrics. One of the key components in DTF printing is the use of UV-curable PET film, which allows for high-quality prints with vibrant colors and excellent durability. In this step-by-step guide, we will walk you through the process of DTF printing using UV-curable PET film.

Step 1: Prepare Your Design

The first step in DTF printing is to prepare your design using design software such as Adobe Illustrator or Photoshop. Once you have finalized your design, make sure to mirror it before printing onto the UV-curable PET film.

Step 2: Print Your Design

Next, print your mirrored design onto the UV-curable PET film using a compatible printer. It is important to use a printer that is specifically designed for DTF printing to ensure the best results.

Step 3: Cure the Ink

After printing, the next step is to cure the ink on the PET film using a UV light source. This process helps to ensure that the ink adheres properly to the film and will transfer effectively onto the fabric.

Step 4: Prepare the Fabric

While the ink is curing, prepare the fabric onto which you will be transferring the design. Make sure the fabric is clean and flat to achieve the best results.

Step 5: Transfer the Design

Once the ink is cured, place the PET film with the design facing down onto the fabric. Use a heat press machine to transfer the design onto the fabric. Apply even pressure and heat for the recommended amount of time.

Step 6: Peel Off the Film

After transferring the design onto the fabric, carefully peel off the PET film to reveal the vibrant and durable print. Your DTF printing with UV-curable PET film is now complete!

In conclusion, DTF printing with UV-curable PET film is a versatile and effective method for transferring designs onto fabrics. By following this step-by-step guide, you can achieve professional results with vibrant colors and excellent durability. Experiment with different designs and fabrics to unleash your creativity and explore the endless possibilities of DTF printing.

Tips for Achieving High-Quality Results in DTF Printing

Digital Transfer Film (DTF) printing is a popular method used in the textile industry for creating high-quality prints on various fabrics. One of the key components of DTF printing is the UV-curable PET film, which plays a crucial role in achieving crisp, vibrant, and durable results. In this article, we will dive into the world of DTF printing with UV-curable PET film and provide some valuable tips for achieving high-quality results.

UV-curable PET film is a type of film that is specially designed to work with UV-curable inks commonly used in DTF printing. This film is known for its excellent adhesion properties, which allow it to bond seamlessly with fabrics, resulting in prints that are smooth and long-lasting. Additionally, UV-curable PET film is resistant to fading and cracking, making it an ideal choice for creating prints that will stand the test of time.

When it comes to achieving high-quality results in DTF printing with UV-curable PET film, there are several key factors to consider. The first and most important factor is proper preparation. Before printing, it is essential to ensure that the PET film is clean and free of any dust or debris that could interfere with the printing process. Additionally, it is important to properly calibrate the printing equipment to ensure accurate color reproduction and sharpness.

Another important tip for achieving high-quality results in DTF printing with UV-curable PET film is to choose the right ink. UV-curable inks are specially formulated to work with PET film and provide vibrant, long-lasting colors. It is important to use high-quality inks from reputable manufacturers to ensure the best results.

In addition to proper preparation and the right ink, it is also essential to pay attention to the printing process itself. When printing with UV-curable PET film, it is important to use the right settings on the printer to ensure optimal adhesion and color reproduction. It is also essential to allow sufficient drying time between each layer of ink to prevent smudging and ensure a crisp, clean print.

Furthermore, it is important to store UV-curable PET film properly to ensure its longevity and performance. PET film should be stored in a cool, dry place away from direct sunlight and heat to prevent degradation. Additionally, it is essential to protect the film from dust and debris to maintain its adhesion properties.

In conclusion, DTF printing with UV-curable PET film is an excellent method for creating high-quality prints on a variety of fabrics. By following the tips outlined in this article, you can achieve crisp, vibrant, and durable results that will impress even the most discerning customers. With proper preparation, the right ink, attention to detail during the printing process, and proper storage, you can create stunning prints that will stand the test of time.

Conclusion

In conclusion, diving into DTF printing using UV-curable PET film opens up a world of possibilities for creating high-quality and vibrant prints. This innovative technology offers a cost-effective and efficient solution for businesses looking to elevate their printing capabilities. By harnessing the power of UV-curable inks and PET film, designers and manufacturers can achieve superior print quality with enhanced durability and color vibrancy. As the demand for customized and unique prints continues to rise, DTF printing with UV-curable PET film is sure to become a staple in the printing industry. Embrace this cutting-edge technology and unlock endless creative potential for your projects.

Email: sales@bigfootdg.com

Add: 4th Floor, Unit 6, Building 11, West Area, Qingyang Street Electronics & Electrical Industrial Park, Zhongyuan District, Zhengzhou City, Henan Province, China